Smart Power Transformer Self-Dehydrating Breather with Pressure gage

Transformer breathing is the process of oil expansion and contraction due to temperature changes in the transformer.

When the oil temperature rises, it pushes the air out of the transformer tank through a device called a transformer breather.

When the oil temperature drops, it draws the air in through the breather. The breather contains silica gel, which absorbs moisture from the air and prevents it from entering the oil.

Not all transformers have breathers, only those that have oil and are not sealed.

Smart breathers are a type of breather that can monitor and control the moisture level, temperature, and pressure of the transformer oil and communicate with a remote system

Table of Contents

Instant Inquiry

Guider of Smart Power Transformer Self-Dehydrating Breather with Pressure gage

Comparison / Why & Which is Better

Traditional Power Transformer Dehydrating Breather

Smart Power Transformer Self-Dehydrating Breather with Pressure gage

| Traditional Power Transformer Dehydrating Breather | Smart Power Transformer Self-Dehydrating Breather with Pressure gage | ||||||

| Composed of silicone cans and oil cups, requiring frequent replacement of silicone and cleaning of oil cups, manual maintenance, and cumbersome process When the crystals or beads of silica gel adsorb the moisture, their color turns from blue to pink. | It consists of a silicone silo, a heating module, a filtering module, a temperature and humidity pressure monitoring module, and a data analysis module. online self-inspection, intelligent maintenance-free | ||||||

| Waste silicone needs to be properly disposed of to avoid contamination | Environmentally friendly recyclable silicone, eliminating secondary pollution | ||||||

| The outer shell is prone to corrosion and rust, and the glass cover is prone to damage, which affects the lifespan and safety of the equipment | Environmentally friendly recyclable silicone, eliminating secondary pollution One-time installation, safe and reliable, Saving more time and labor cost |

Product Show & Details

Product Specification & Selection

| Model | Installation Position | Transformer oil Volume | silica gel Weight | Transformer Breather Weight | installation requirement | |||||||

| MYJZ-100T | Voltage regulating switch Transformer body | 10 Tons / 10000KGS | 1.5 KGS | 10 KGS | for 35kV Transformer on load tap changer 35kV main transformer body | |||||||

| MYJZ-200T | Transformer body | 10-60 Tons / 60000KGS | 3 KGS | 15 KGS | Suitable for 110kV, 220kV on load voltage regulating switches, transformer body | |||||||

| MYJZ-400T | Transformer body | more than 60 Tons/60000KGS | 6 KGS | 25 KGS | Suitable for transformer bodies of 500kV and above | |||||||

Product Future

Your Power Transformer Protector

- Eco

- Intelligence

- Maintenance-free

- The main function of the Smart Power Transformer Dehydrating Breather is to remove and dry sundries and moisture entering the air of the transformer oil conservator due to the change of transformer oil temperature, to maintain the insulation strength of transformer oil.

- At present, traditional suspended dehumidifiers are widely used, and maintenance personnel must regularly inspect them. Once the desiccant changes color, maintenance personnel must replace it promptly on time, which not only increases the workload but also increases the safety hazards of equipment operation. Therefore, it is necessary to use a new type of Smart Power Transformer Dehydrating Breather, which has the following features: automatic constant temperature heating and drying, recyclable desiccant, and the ability to detect the conductivity of the internal and connecting pipes of the moisture absorber; Equipped with intelligent communication protocols and interfaces, real-time monitoring, as well as data storage, analysis, mining, and other functions, achieving a maintenance-free intelligent solution for power Smart Power Transformer Dehydrating Breathers.

- Under the requirements of the State Grid Corporation of China for the development of modern smart grid data applications, higher requirements have been put forward for equipment monitoring and maintenance. Traditional moisture absorbers lack necessary monitoring methods when left unattended, and are cumbersome in terms of maintenance and environmental protection. The new MYJZ series maintenance-free intelligent moisture absorbers play a significant role and significance in meeting the requirements of smart grid data monitoring, achieving the “dual carbon” goals, and promoting green environmental protection.

Derived functions of MYJZ series Smart Power Transformer Dehydrating Breather

- Monitor the temperature and humidity of the air in the transformer oil conservator 24H x 30 Days.

- Intelligent protection of the external operating environment, preventing condensation at the bottom from freezing and affecting the moisture absorber.

- The indicator light alarm is convenient for inspection personnel to check and can send an alarm signal to a remote location through preset contacts.

- Connect to the main station auxiliary control panel through the RS485 interface output or network interface module of the IEC61850 communication protocol

Working Principle

- During the normal operation of the transformer, due to the thermal expansion of the transformer insulation oil, the air in the conservator will pass through the pipeline of the respirator, which is similar to breathing.

- When external air is sucked in through a moisture absorber, the air passes through a stainless steel metal filter screen to filter out dust and floating objects in the air, and then flows through a silicone drying chamber.

- The moisture in the air is absorbed by the desiccant, achieving the goal of drying the air. The moisture absorber continuously monitors the internal air humidity and transmits the monitoring results to the system control module.

- When the air humidity exceeds the programmed value, it indicates that the desiccant has temporarily lost its water absorption capacity and reached a saturation state.

- When the internal air is exhaled through the moisture absorber, and the pressure sensor detects a positive signal of internal air pressure, the control unit will activate the heating element laid in the silicone, and the moisture absorber heating module will automatically start, drying the desiccant moisture, thus achieving the regeneration and utilization of environmentally friendly silicone.

- The activation of the heating element can only be triggered when exhaling air, ensuring that moist air does not enter the conservator in the form of high-temperature steam.

- The high-temperature steam generated during the regeneration process condenses on the inner wall of the glass and flows out through the stainless steel filter screen at the bottom of the moisture absorber to ensure the safety and effectiveness of the regeneration process.

- When the ambient temperature is below the programmed value (such as 10 ° C), the bottom auxiliary heating module automatically starts to prevent blockage of the bottom breathing port due to freezing, ensuring that the moisture absorber always maintains a safe and good working condition.

- When the moisture absorber malfunctions (such as a control system or heating module malfunction), the external red indicator light of the control box will alarm for easy inspection by operators. Remote alarm signals can be sent through preset contact switches, and all status parameters (temperature, humidity, heating status, fault status, etc.) can be output through the RS485 interface. Remote monitoring of the moisture absorber status can be achieved through remote communication.

- At the same time, customers can customize and select network output interface modules that comply with the IEC61850 communication protocol according to their needs, to achieve the access of moisture absorber equipment status information to the substation main station auxiliary control platform.

Product advantages 01

(Comparison of advantages and disadvantages between the new and old models)

Item | Traditional Power Transformer Dehydrating Breather | Smart Power Transformer Self-Dehydrating Breather with Pressure gage | |||||||

Installation |

| One-time installation, safe and reliable, Saving more time and labor cost | |||||||

Maintain |

| Maintenance-free, clean, and low-carbon, intelligent operation and maintenance | |||||||

Other |

|

| |||||||

Product advantages 02

(Comparison of maintenance costs)

| Item | Traditional Power Transformer Dehydrating Breather | Smart Power Transformer Self-Dehydrating Breather with Pressure gage | |||||||

| Operation and maintenance management | Complicated procedures such as process approval, weather review, work ticket issuance, scheduling, and changing gas signals | Remote inspection significantly reduces the workload of operation and maintenance personnel | |||||||

| Change times/year | 2 times(No upper limit for humid areas) | NO | |||||||

| Cost of replacing silicone/year | $1000 /unit * 4=$4000 (one main transformer) | NO | |||||||

| Labor cost/year | $3000/ person*2 peroson*2 times=$6000 | NO | |||||||

| Other Costs/year | $1000/time*2=$2000 | NO | |||||||

| In Total Cost/year | $12,000 | one time | |||||||

The Advantage of Smart Power Transformer Self-Dehydrating Breather with Pressure gage

| Main features |

| |||||||

| Intelligent judgment of transformer breathing status |

| |||||||

| Withstand various harsh environments |

| |||||||

| Data recording function |

| |||||||

| Extended function |

| |||||||

DATA SHEET 01

| Technology DATA | ||||||||

| Installation position | Oil filling equipment Oil conservator Breathing port | |||||||

| Environmental temperature | (-40℃ -60℃) | |||||||

| The core components | all imported industrial-grade components | |||||||

| Material performance | anti-transformer oil, ultraviolet ray, salt fog, temperature, and humidity alternation (GJB150A-2009 Military Industry Three Defense Standard) | |||||||

| Ventilation resistance | W0.01Mpa | |||||||

| Desiccant | colorless and environmentally friendly renewable silicone, with a regeneration frequency of no less than 200 times | |||||||

| Adsorption capacity |

| |||||||

| IP Grade | IP65 (according to IEC 60529 standard) | |||||||

| Flange connection | standard configuration DN25, non-standard and customizable | |||||||

| Display function | with LED display light, LCD screen (optional) | |||||||

| Equipment weight |

| |||||||

DATA SHEET 02

| 1. Power /Input Voltage | Voltage 230VAC±10% 50-60HZ | ||||||

| Heating Current |

| ||||||

| DATA Output | Singal output RS-485 (Customers can choose to order a network interface module that complies with the ICE61850 communication protocol) | ||||||

| 2. Control Box | |||||||

| Cable interface | 1xM20x1.5/2xM16x1.5 | ||||||

| Wiring terminal | 2.5 mm² AWG 12-8 flexible cable | ||||||

| 3. Indicator Light | Yellow | Green | Red | |||

| Normal | Bright | turn off | turn off | |||

| Fault | Bright | turn off | Twinkle, Bright | |||

| Heating | Bright | Bright | turn off | |||

| 4. Signal Switch | |||||||

| Heating Singal | 1 normally open contact, with a maximum value of 5A at 230V/AC | ||||||

| Fault | 1 normally open contact, with a maximum value of 5A at 230V/AC | ||||||

| Run | 1 normally Closed contact, with a maximum value of 5A at 230V/AC | ||||||

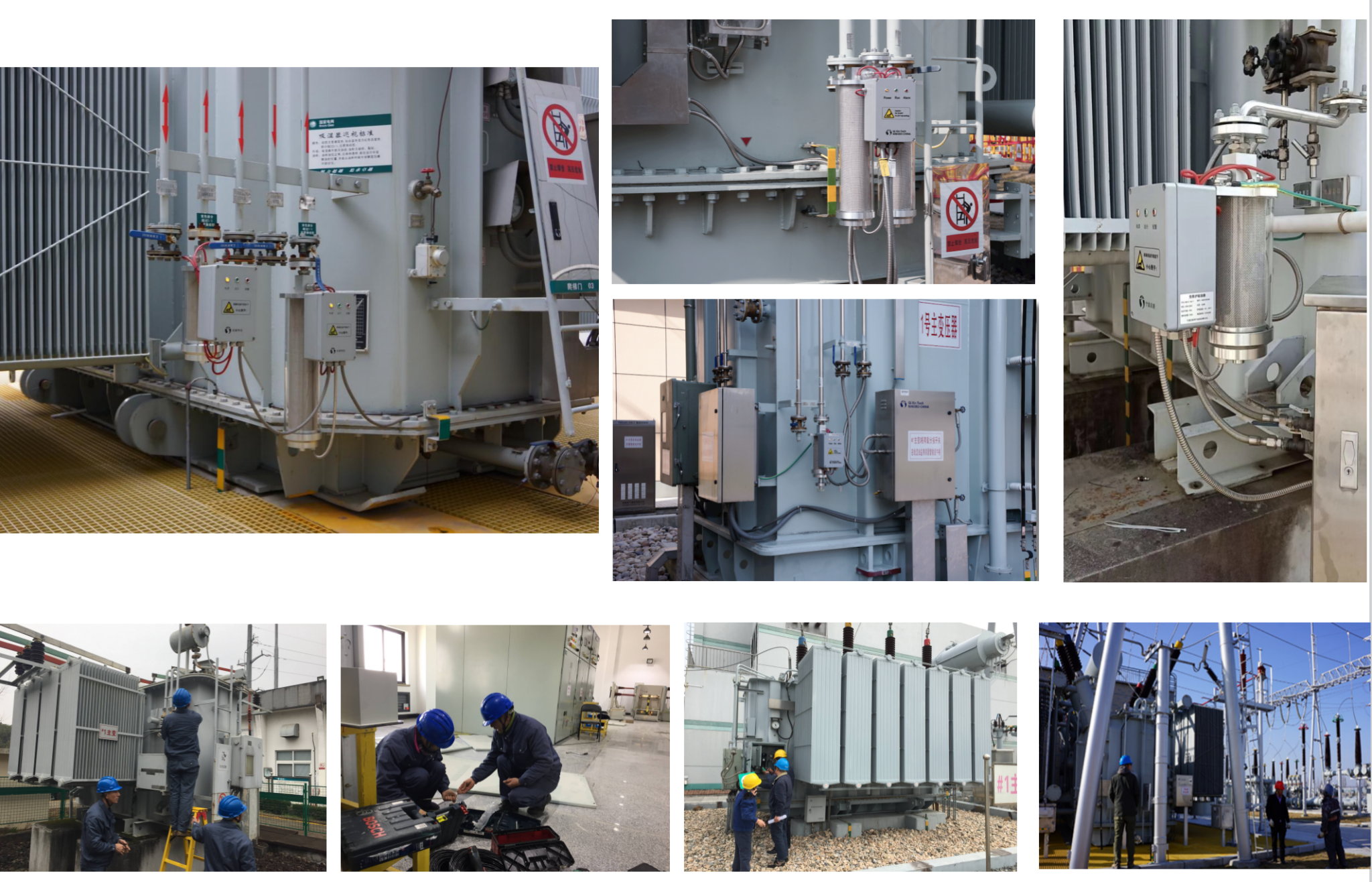

Engineering Project Cases 01

This Smart Power Transformer Dehydrating Breather which we developed now widely used in power transformers with voltage levels of 750kV, 500kV, 220kV, 110kV, and 35kV.

Users include major customers of State Grid, Southern Power Grid, power plants, rail transit, and enterprise electricity consumption.

Engineering Project Cases & Team Work Installation 02

Type Testing

- Type Testing is a test conducted to verify whether a product can meet all the requirements of the technical specifications

- Our Smart Power Transformer Dehydrating Breather has passed the type test report of the national authoritative institution – Shenyang Transformer Research Institute.

- At different environmental temperatures, the product has undergone more than 100 complete regeneration and heating cycles of silica gel.

- After testing, the chemical composition and physical properties of silica gel have not changed under the same air flow rate and environmental temperature.

Global & Europe Market Certification

Our Products Comply with EU Standards

Company ISO Certification

About Qi Xin Power Grid Technology-History

15 years Power Grid Operation and Maintenance Service Providers and manufacturers

Ningbo Qixin Electrical Technology Co., Ltd. is a technology-oriented enterprise that specializes in online transmission and transformation equipment. It was established in late 2009 and has 15 years of experience in providing and manufacturing power grid operation and maintenance services. It has advanced equipment and strong technical force to independently develop and produce various products for power equipment operation environment regulation and control, such as:

- transformer on load tap changer online oil filtering device

- transformer intelligent maintenance-free respirator

- SF6 gas leakage alarm system

- operation ambient intelligence intelligent control device

- GIS assembly

- cable welding dust-free workshop management

- 30 intelligent control oil replenishing device

- Internet of Things intelligent flange

- the intelligent vacuum oil sampling system of live working series

- the live vacuum oil replenishing robot

Many of its products have obtained invention patent certificates from the China National Intellectual Property Administration for their advanced technology. It also offers comprehensive electrical environment management solutions, power equipment safety operation, and power system software development.

About Qi Xin Power Grid Tech-Future

- Before, we have been engaged in the operation, maintenance, and service of the local power grid

- Now we are more committed to the research and develop future Smart Grids

The company is a professional and focused enterprise that specializes in smart grid solutions. It has a standard factory building of 2000 square meters and an office area of 500 square meters. It has 108 employees, of which 80% are college graduates or above. It has 8 major departments, including:

- research and development center

- CNC machining center

- design center

- technical support and service center

It has advanced equipment such as laser welding machines, CNC lathes, CNC milling machines, fully automatic pipe bending machines, automatic leak detection platforms, constant temperature testing devices, and standard drying rooms.

The company follows the corporate spirit of “professionalism, focus, meticulousness, and excellence” and the business philosophy of “innovating to lead the market, exploring the market with quality, and consolidating the market with service”. It constantly innovates and pursues excellence, and strives to achieve the great wish of “smart grid”.

Our Customers & Cooperation Partners

- State Grid

- Southern Power Grid

- other Provincial power companies

- Five major power generation groups

- Sinopec

- Petro China

- Rail transit industry

- Hefei ABB Transformer Co., Ltd.,

- Guangzhou Zhongshan ABB Transformer Co., Ltd

- Siemens (Wuhan) Co., Ltd.,

- Siemens (Guangzhou) Co., Ltd., and

- TBEA Hengyang Transformer Co., Ltd,

- Jiangsu Huapeng Transformer Co., Ltd.,

- Nanjing Liye Transformer Co., Ltd.,

- Sanbian Technology Co., Ltd.,

- Zhejiang Power Transformer Co., Ltd.

- other large domestic power companies