Smart Power Transformer Self-Dehydrating Dual Tank Breather with Pressure gage MYJZ-400T-Dual silica 6KGS-use for up to 500KV Power Transformer

Model: MYJZ-400T

Installation Position: Voltage regulating switch and power transformer

Transformer Oil Volume: more than 60 Tons

Silica Gel Weight: 6KGS

Breather Weight: 25KGS

Installation requirement: Suitable for 500KV and more on load voltage regulating switches, transformer bodies

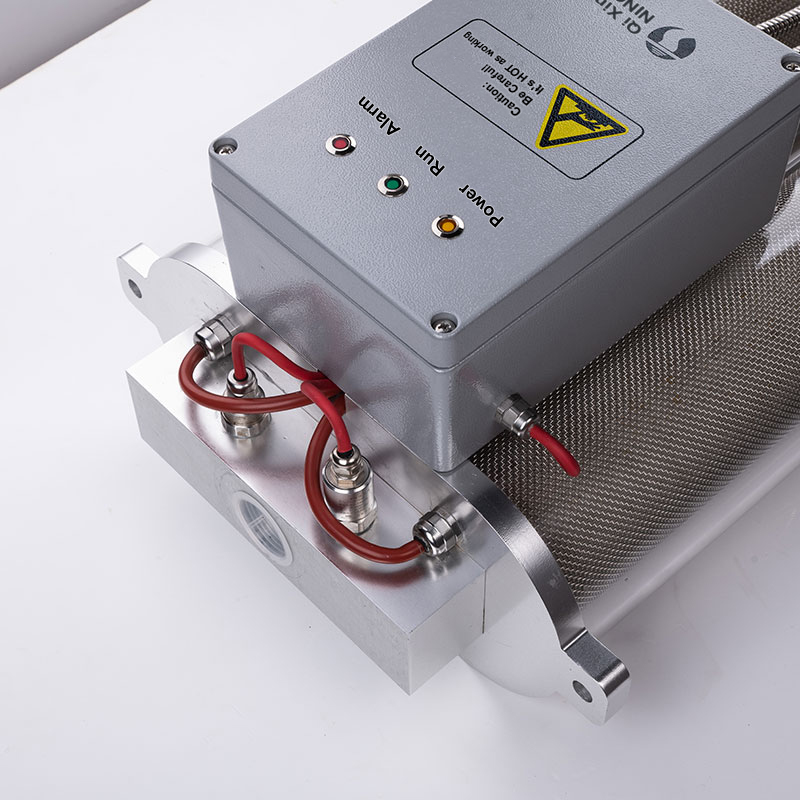

The Smart Power Transformer Dehydrating Breather is a new type of device that can remove and dry the moisture and dust in the transformer oil conservator air.

It can maintain the insulation strength of transformer oil and achieve a maintenance-free intelligent solution. It has the following features:

- Automatic constant temperature heating and drying, recyclable desiccant

- Conductivity detection of the internal and connecting pipes of the moisture absorber

- Intelligent communication protocols and interfaces, real-time monitoring, data storage, analysis, and mining

- Indicator light alarm and remote alarm signal

- RS485 interface output or network interface module of the IEC61850 communication protocol

The Smart Power Transformer Dehydrating Breather can meet the requirements of smart grid data monitoring, achieve the “dual carbon” goals, and promote green environmental protection. It is superior to the traditional moisture absorbers that lack monitoring methods, requires regular replacement of desiccant, and pose safety hazards.

The Smart Power Transformer Dehydrating Breather can also monitor the temperature and humidity of the air in the transformer oil conservator 24H x 30 Days and protect the external operating environment from freezing and condensation.

Derived functions of MYJZ series Smart Power Transformer Dehydrating Breather

1. Monitor the temperature and humidity of the air in the transformer oil conservator 24H x 30 Days.

2. Intelligent protection of the external operating environment, preventing condensation at the bottom from freezing and affecting the moisture absorber.

3. The indicator light alarm is convenient for inspection personnel to check and can send an alarm signal to a remote location through preset contacts.

4. Connect to the main station auxiliary control panel through the RS485 interface output or network interface module of the IEC61850 communication protocol

Inquiry.

Contact WeChat![]()

Tony

IoT Solutions.

connecting and remote control everything

We’re professional and Special to built

Long Range Wireless Solutions

We have more than 1000+ IoT Smart Devices

Easy to Built Smart Factory,

Smart Industry4.0, Smart Farm, Smart Energy,

get all basic DATA , and Show you anytime,anywhere

www.iotsss.com

Global Advanced Smart Solutions Supplier

Smart Power Transformer Self-Dehydrating Dual Tank Breather with Pressure gage MYJZ-400T-Dual silica 6KGS-use for up to 500KV Power Transformer

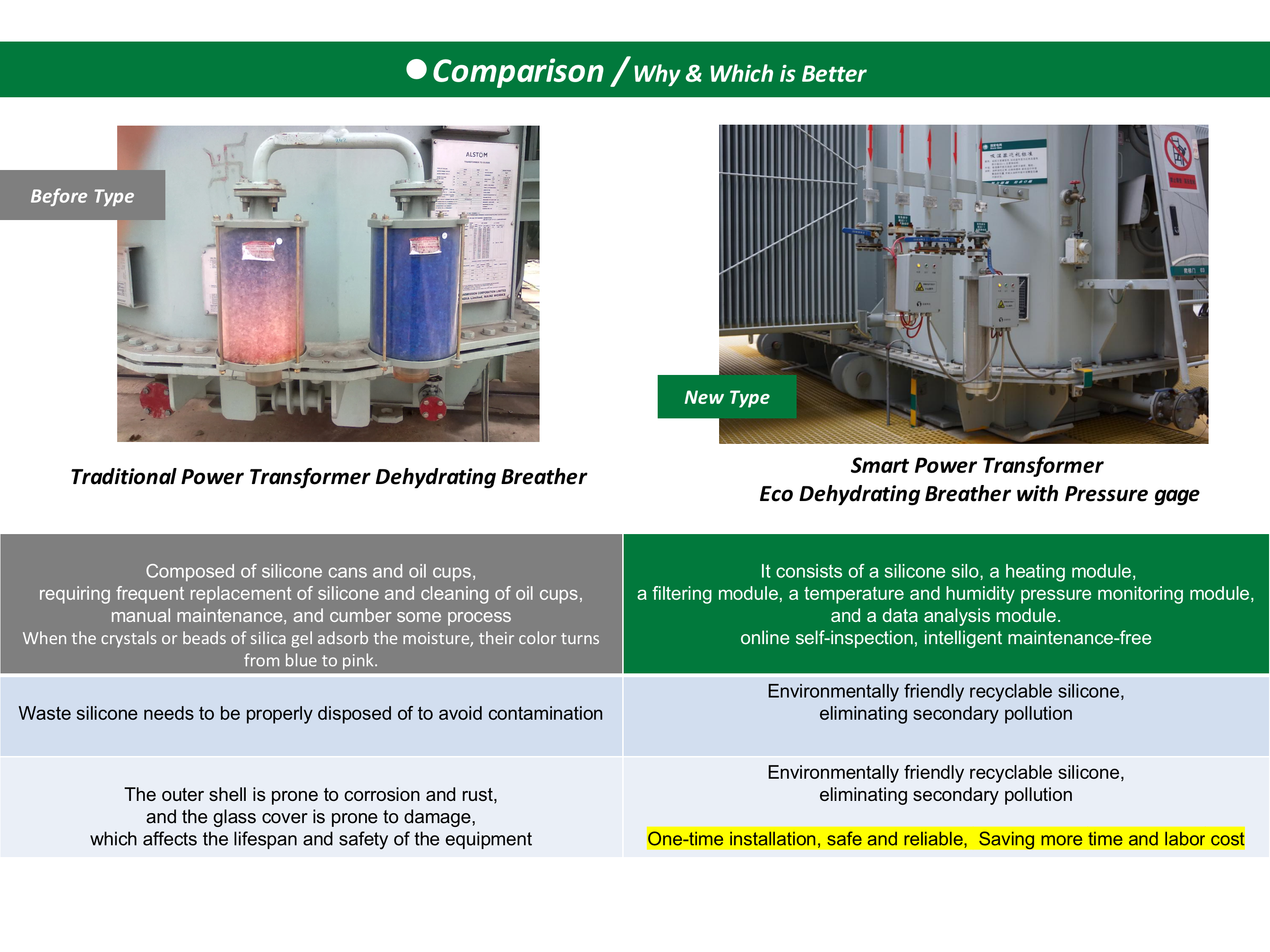

Comparison / Why & Which is Better

- future of Traditional Power Transformer Dehydrating Breather

- Composed of silicone cans and oil cups, requiring frequent replacement of silicone and cleaning of oil cups, manual maintenance, and cumbersome process When the crystals or beads of silica gel adsorb the moisture, their color turns from blue to pink.

- Waste silicone needs to be properly disposed of to avoid contamination

- The outer shell is prone to corrosion and rust, and the glass cover is prone to damage, which affects the lifespan and safety of the equipment

- future of Smart Power Transformer Self-Dehydrating Breather with Pressure gage

- It consists of a silicone silo, a heating module, a filtering module, a temperature and humidity pressure monitoring module, and a data analysis module. online self-inspection, intelligent maintenance-free

- Environmentally friendly recyclable silicone, eliminating secondary pollution

- Environmentally friendly recyclable silicone, eliminating secondary pollution One-time installation, safe and reliable, Saving more time and labor cost

-

Product Specification & Selection

| Model | Installation Position | Transformer oil Volume | silica gel Weight | Breather Weight | installation requirement |

| MYJZ-100T | Voltage regulating switch

Transformer body |

10 Tons | 1.5 KGS | 10 KGS | for 35kV Transformer

on load tap changer 35kV main transformer body |

| MYJZ-200T | Transformer body | 10-60 Tons | 3 KGS | 15 KGS | Suitable for 110kV, 220kV on load voltage regulating switches,

transformer bodies |

| MYJZ-400T | Transformer body | > 60 Tons | 6 KGS | 25 KGS | Suitable for transformer bodies of 500kV and above |

- Product Future

- The main function of the Smart Power Transformer Dehydrating Breather is to remove and dry sundries and moisture entering the air of the transformer oil conservator due to the change of transformer oil temperature, to maintain the insulation strength of transformer oil.

- At present, traditional suspended dehumidifiers are widely used, and maintenance personnel must regularly inspect them. Once the desiccant changes color, maintenance personnel must replace it promptly on time, which not only increases the workload but also increases the safety hazards of equipment operation. Therefore, it is necessary to use a new type of Smart Power Transformer Dehydrating Breather, which has the following features: automatic constant temperature heating and drying, recyclable desiccant, and the ability to detect the conductivity of the internal and connecting pipes of the moisture absorber; Equipped with intelligent communication protocols and interfaces, real-time monitoring, as well as data storage, analysis, mining, and other functions, achieving a maintenance-free intelligent solution for power Smart Power Transformer Dehydrating Breathers.

- Under the requirements of the State Grid Corporation of China for the development of modern smart grid data applications, higher requirements have been put forward for equipment monitoring and maintenance. Traditional moisture absorbers lack necessary monitoring methods when left unattended, and are cumbersome in terms of maintenance and environmental protection. The new MYJZ series maintenance-free intelligent moisture absorbers play a significant role and significance in meeting the requirements of smart grid data monitoring, achieving the “dual carbon” goals, and promoting green environmental protection.

- Working Principle

- During the normal operation of the transformer, due to the thermal expansion of the transformer insulation oil, the air in the conservator will pass through the pipeline of the respirator, which is similar to breathing.

- When external air is sucked in through a moisture absorber, the air passes through a stainless steel metal filter screen to filter out dust and floating objects in the air, and then flows through a silicone drying chamber.

- The moisture in the air is absorbed by the desiccant, achieving the goal of drying the air. The moisture absorber continuously monitors the internal air humidity and transmits the monitoring results to the system control module.

- When the air humidity exceeds the programmed value, it indicates that the desiccant has temporarily lost its water absorption capacity and reached a saturation state.

- When the internal air is exhaled through the moisture absorber, and the pressure sensor detects a positive signal of internal air pressure, the control unit will activate the heating element laid in the silicone, and the moisture absorber heating module will automatically start, drying the desiccant moisture, thus achieving the regeneration and utilization of environmentally friendly silicone.

- The activation of the heating element can only be triggered when exhaling air, ensuring that moist air does not enter the conservator in the form of high-temperature steam.

- The high-temperature steam generated during the regeneration process condenses on the inner wall of the glass and flows out through the stainless steel filter screen at the bottom of the moisture absorber to ensure the safety and effectiveness of the regeneration process.

- When the ambient temperature is below the programmed value (such as 10 ° C), the bottom auxiliary heating module automatically starts to prevent blockage of the bottom breathing port due to freezing, ensuring that the moisture absorber always maintains a safe and good working condition.

- When the moisture absorber malfunctions (such as a control system or heating module malfunction), the external red indicator light of the control box will alarm for easy inspection by operators. Remote alarm signals can be sent through preset contact switches, and all status parameters (temperature, humidity, heating status, fault status, etc.) can be output through the RS485 interface. Remote monitoring of the moisture absorber status can be achieved through remote communication.

- At the same time, customers can customize and select network output interface modules that comply with the IEC61850 communication protocol according to their needs, to achieve the access of moisture absorber equipment status information to the substation main station auxiliary control platform.

- Product advantages 01 (compared with before type and new type)

- DATA SHEET

- Engineering Project Cases

Related products

-

IoT Smart Grid

Smart Power Transformer Self-Dehydrating Breather with Pressure gage MYJZ-200T-silica 3KGS-use for 110KV 120KV Power Transformer

Rated 0 out of 5$5,800.00Original price was: $5,800.00.$4,980.00Current price is: $4,980.00. Add to cart -

IoT Smart Grid

Smart Power Transformer Self-Dehydrating Breather with Pressure gage MYJZ-100T-silica 1.5KGS-use for 35KV Power Transformer

Rated 0 out of 5$3,800.00Original price was: $3,800.00.$2,980.00Current price is: $2,980.00. Add to cart